Signs You Need To Replace Your Industrial Padlocks

Industrial padlocks maintain the security and safety of valuable assets, sensitive equipment, and private property. However, like all mechanical devices, padlocks have a finite lifespan and can wear out over time due to constant use, environmental factors, or tampering attempts.

Ignoring the signs you need to replace your industrial padlocks increases the risk of theft, damage, or unauthorized access. To maintain secure operations, it’s vital to know when it’s time to retire and upgrade your industrial padlocks.

Rust and Corrosion

One of the most visible signs of a deteriorating padlock is the presence of rust and corrosion. Industrial padlocks are often exposed to harsh elements such as rain, snow, or humidity, especially if they’re used outdoors. Over time, moisture can cause the metal components of the padlock to corrode, weakening their structural integrity. A rusted padlock is harder to operate, and the locking mechanism and the shackle may eventually degrade to the point where they’re no longer secure.

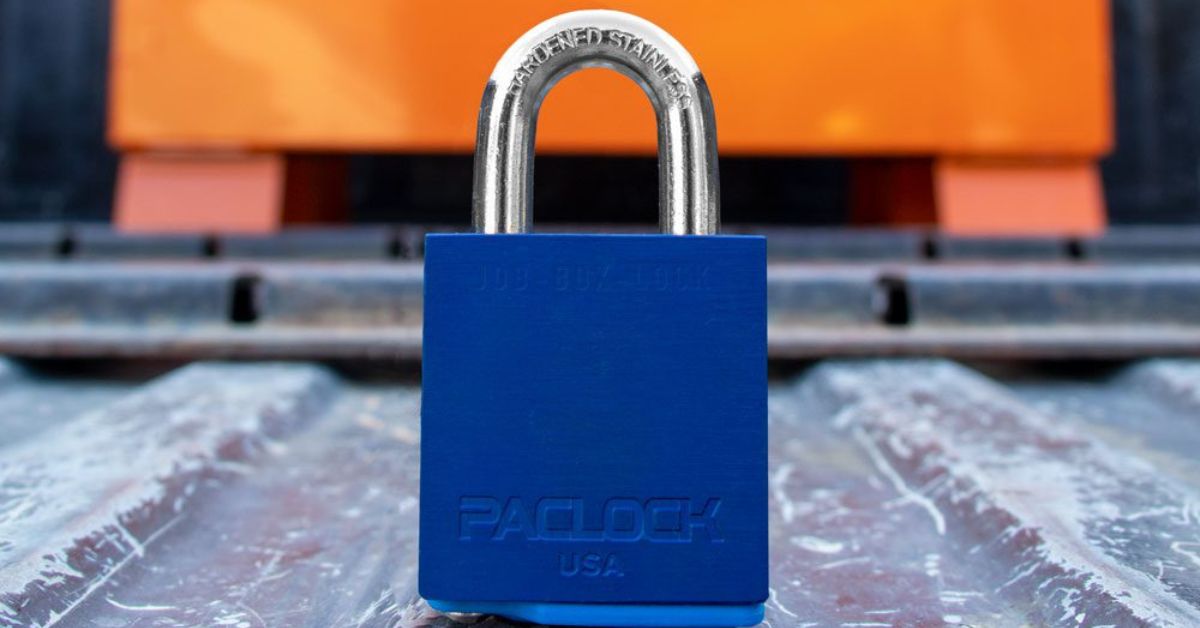

If you notice that your padlock’s exterior is noticeably corroded, or if it feels stiff when you try to insert or turn the key, these are clear indicators that you must replace it. If you find your standard locks corrode or generally fall apart too quickly, you may need to invest in heavy-duty padlocks to guarantee security.

Difficulty Locking or Unlocking

Another sign that your industrial padlock might be failing is when it becomes increasingly difficult to lock or unlock. This issue can stem from internal wear and tear or debris buildup inside the locking mechanism. If you frequently find yourself struggling to turn the key, or if the shackle doesn’t snap into place smoothly, the lock could be nearing the end of its usability.

While lubrication can sometimes provide temporary relief from this issue, it’s only a short-term fix. A padlock that routinely exhibits operational difficulties can lead to frustration and, more importantly, jeopardize security in critical situations. It’s always better to err on the side of caution and invest in a new padlock rather than risk being unable to lock or unlock yours when needed.

Visible Damage From Tampering

Industrial padlocks are often targets for attempted breaches, whether from cutting, drilling, or picking. If you notice visible damage, such as scratches, dents, or deformations on the shackle or locking mechanism, these are warning signs that the padlock has been tampered with. Even if the breach was unsuccessful, a damaged padlock may no longer provide the same level of security as before.

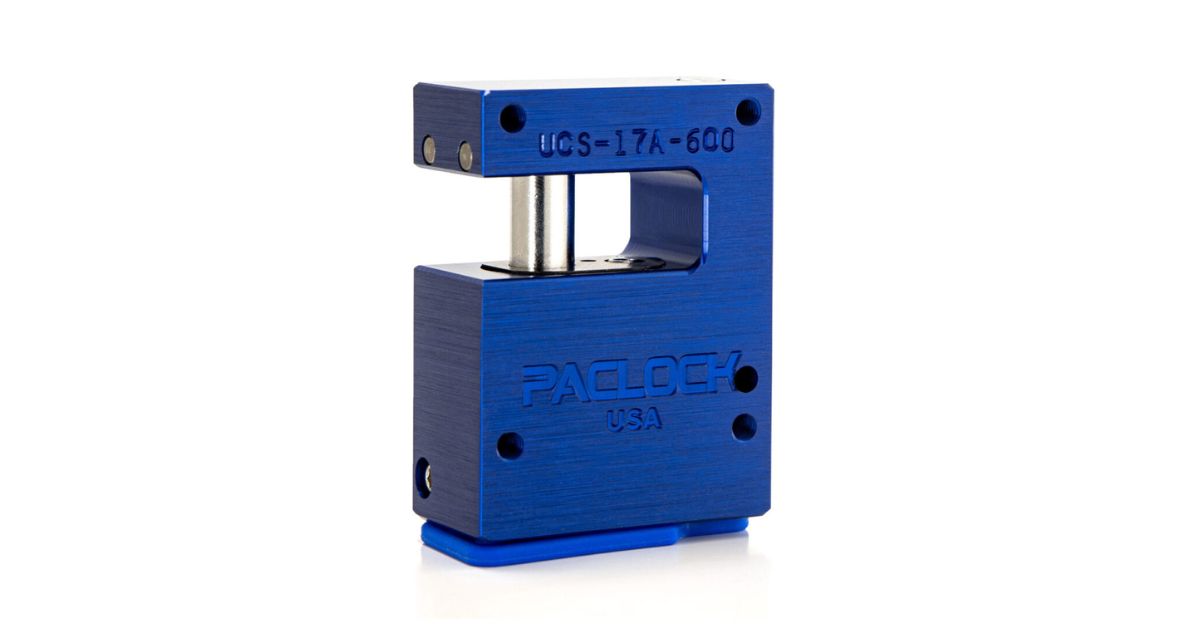

Padlocks compromised by tampering are more likely to fail under pressure, potentially putting your assets at risk. Upgrading to a high-security padlock with advanced anti-tampering features, such as shrouded shackles or pick-resistant mechanisms, can provide enhanced protection against future attempts.

Key Wear and Misalignment

Keys and locks are designed to work together with precision, but over time, both components can wear down. If you notice that your key has become bent, chipped, or worn, or if it no longer aligns correctly with the padlock’s cylinder, it might be time to replace the entire unit. A poorly functioning key can cause damage to the internal mechanisms of the lock, leading to jams or other malfunctioning issues.

If you find yourself needing to use excessive force to insert the key or turn it, these are red flags. Replacing the lock and key will restore ease of use and create better security moving forward.

Outdated Security Features

Security threats evolve over time, and older padlock models may no longer offer sufficient protection against modern intrusion techniques. If your industrial padlocks rely on outdated designs, they might be vulnerable to advanced lock-picking tools or brute force attacks. For example, traditional pin-tumbler locks, while once standard, are now easily bypassed by skilled intruders.

Upgrading to modern industrial padlocks with updated security features, such as keyless entry options, electronic locking mechanisms, or biometric systems, can boost your overall security strategy.

Broken or Weak Shackle

The shackle is the most critical component of a padlock, as it’s exposed to potential cutting or prying attacks. If the shackle shows signs of wear, such as cracks, bending, or weakness, it can no longer sufficiently protect your property. Even a small deformity can compromise the padlock’s ability to resist force and hold up against tampering.

Routinely inspect the shackle, especially industrial padlocks subjected to heavy use or extreme conditions. If you identify the above signs of damage, replacing the padlock is a necessary next step for continued security.

Frequent Malfunctions

Padlocks that regularly malfunction or require excessive maintenance can indicate deeper issues that necessitate replacement. Frequent occurrences of sticking mechanisms, keys getting stuck, or the shackle failing to lock properly are telltale signs that the padlock is no longer reliable.

Industrial settings demand dependable security solutions, so relying on a malfunctioning padlock is not worth the risk. Investing in a high-quality replacement guarantees smooth operation and reduces the likelihood of future problems.

Key Loss

If the keys to your industrial padlock go missing, you must replace the lock to maintain security. Lost keys may fall into the wrong hands, posing a major safety risk to your property and operations. While rekeying might be an option for some padlocks, it’s often more convenient and cost-effective to replace the entire unit, especially if the lock already shows signs of wear.

Additionally, consider switching to padlocks with key control systems or combinations, which allow for greater control and monitoring of who has access to the lock, minimizing the risk of unauthorized duplication.

Environmental Impact

Industrial padlocks exposed to extreme temperatures, salt water, or heavy industrial pollutants may experience accelerated wear and tear, even if they’re designed for harsh environments. Over time, environmental damage can compromise the functionality and lifespan of the padlock, necessitating replacement sooner than anticipated.

Pay attention to how your padlocks respond to their specific environment. Look for signs of weakened performance or visible deterioration, and consider replacing them with weather-specific or corrosion-resistant models if required.

Keep Your Locks Secure

Industrial padlocks are a vital component of any security system, and their performance directly impacts the safety of your assets. Recognizing the signs of a failing padlock can help you avoid unnecessary risks and maintain ongoing protection. Regular inspections paired with timely replacements are key to maintaining a reliable security system in rigorous industrial settings.

Recent Comments