The Different Types of Trailer Couplers Explained

Knowing the different types of trailer couplers makes it easier to see how these essential parts link trailers and towing vehicles safely and securely. Couplers are built to handle heavy loads, keep things steady during transport, and help protect both your gear and your team.

To choose the best coupler, focus on design, materials, and safety standards, not just the price tag. Investing in a high-quality coupler pays off with less wear and tear, better control, and a longer lifespan, especially in tough industrial settings where a failure can quickly turn into expensive downtime.

What a Trailer Coupler Does and Why Quality Matters

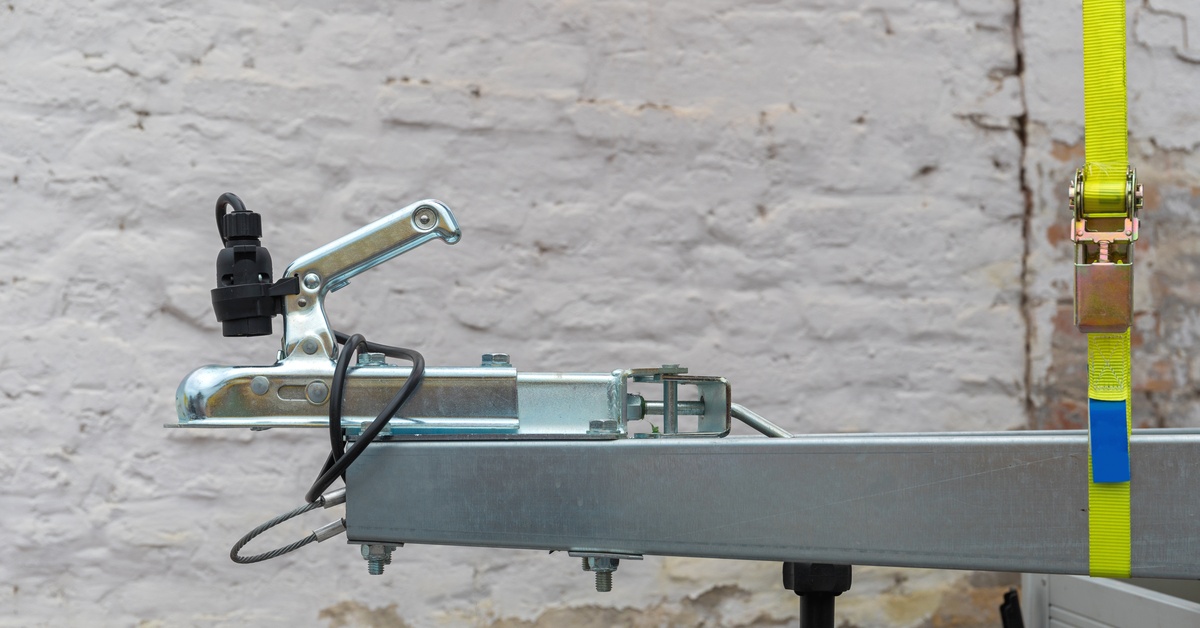

A trailer coupler connects the trailer tongue to the hitch ball or pintle hook on a towing vehicle. This connection must handle constant stress from acceleration, braking, vibration, and uneven terrain.

Inferior couplers often use thin steel or inconsistent welds, which can lead to deformation or failure over time. Premium couplers use thicker steel, precision machining, and reinforced locking mechanisms to maintain a secure connection under load, even during frequent starts and stops.

Manufacturers that follow strict safety standards test couplers for load ratings, fatigue resistance, and corrosion protection. These tests ensure the coupler performs reliably in construction, utility, and industrial applications where trailers are used daily. Investing in a higher-quality coupler protects cargo, equipment, and people on the job site while reducing long-term replacement costs.

Straight Tongue Couplers

Straight tongue couplers mount directly to a straight trailer tongue and are among the most common designs. These couplers typically use stamped or forged steel, depending on the quality level.

High-end models rely on forged steel because it delivers greater strength and a more uniform grain structure than stamped alternatives, improving resistance to cracking under repeated stress.

Precision-fit latch systems help reduce play between the hitch ball and coupler socket. Reduced movement improves towing stability and minimizes long-term wear on both the coupler and hitch ball. Many premium straight tongue couplers also feature corrosion-resistant coatings, such as zinc plating or powder coating, to withstand moisture, chemicals, and road debris.

A-Frame Trailer Couplers

A-frame couplers attach to trailers with triangular tongues and distribute load across two mounting points. This design improves stability and reduces stress concentration at a single connection point. Quality A-frame couplers use heavy-gauge steel and reinforced mounting flanges to handle higher tongue weights without bending or distortion.

Manufacturers often weld these couplers using controlled processes that ensure consistent penetration and strength. Better models also incorporate hardened locking components that resist deformation during repeated coupling and uncoupling. These features make A-frame couplers a strong choice for equipment trailers and industrial hauling where reliability matters.

Adjustable Channel Couplers

Adjustable channel couplers mount to a vertical channel, allowing users to adjust the hitch height. This flexibility helps maintain proper trailer level when towing with different vehicles, which improves braking performance and tire wear. High-quality adjustable couplers rely on thick steel channels and precision-drilled mounting holes to maintain alignment under load.

Premium designs use grade-rated hardware and reinforced gussets to prevent shifting during transport. The best models also include secure locking mechanisms that maintain adjustment settings even on rough terrain. Adjustable channel couplers suit fleets and contractors who tow multiple trailers with varying vehicle setups.

Pintle Hook Couplers

Pintle hook couplers pair with pintle hitches and support heavy-duty and off-road applications. These couplers excel in environments that demand articulation, such as construction sites or uneven industrial yards where traditional ball couplers may bind. Manufacturers typically build pintle couplers from cast or forged steel to handle extreme loads and shock forces.

High-quality pintle couplers meet or exceed SAE and DOT standards for load capacity and durability. Tight tolerance manufacturing ensures a secure fit while still allowing necessary movement. This balance improves safety without sacrificing performance in rugged conditions.

Gooseneck and Fifth-Wheel Couplers

Gooseneck and fifth-wheel couplers serve large trailers that require increased load capacity and stability. These systems mount in the truck bed and distribute weight more evenly across the towing vehicle, which improves control during highway transport. Quality couplers in this category use high-strength steel alloys and hardened locking jaws to manage substantial tongue weights.

Manufacturers design these couplers with precise machining to ensure smooth engagement and release. Advanced coatings and sealed components protect against corrosion and debris intrusion. These features extend service life and reduce maintenance demands in industrial and agricultural operations.

Safety, Materials, and Security Features

Trailer couplers rely on more than basic design to deliver safe performance. Material selection and finishing processes directly affect strength and longevity. High-grade carbon steel and alloy steel provide superior tensile strength and resistance to cracking under heavy loads. Protective finishes guard against rust, which can weaken structural integrity over time and compromise safety.

Many users add security accessories, such as a trailer coupler padlock, to deter theft and protect valuable equipment. Quality couplers often integrate lock-compatible designs without compromising structural strength or ease of use.

Key features that separate premium couplers from lower-grade options include:

- Forged or cast steel construction for consistent strength

- Reinforced latch mechanisms that resist wear

- Corrosion-resistant coatings for harsh environments

- Compliance with SAE and DOT safety standards

These features reflect careful engineering and quality control rather than cost-cutting shortcuts.

Choosing the Right Trailer Coupler for Your Application

Selecting the right trailer coupler requires matching load ratings, trailer design, and operating conditions. Buyers should always verify gross trailer weight and tongue weight ratings before purchasing to avoid overloading components. Regular inspection also helps identify wear early and maintain safe operation.

When choosing a trailer coupler, consider how often you’ll need to connect and disconnect your trailer, the terrain you’ll encounter, and whether you need extra features like sway reduction or shock absorption. Some couplers excel in rough conditions or heavy use, while others are designed for maximum stability or ease of operation. Taking the time to evaluate these factors ensures you select a coupler that meets industry standards and aligns with your specific workflow and safety needs.

H To O Supply offers access to industrial-grade tools and safety equipment from trusted manufacturers. Our focus on quality materials and proven brands helps customers avoid failures caused by inferior components. Reliable couplers reduce downtime, protect investments, and support safer transport across industries.

Bringing It All Together: Your Coupler Decision

Explaining the different types of trailer couplers shows how design, materials, and safety standards influence performance and reliability. High-quality couplers use stronger metals, better manufacturing processes, and tested safety features to outperform lower-grade options.

Choosing the right coupler protects equipment, improves towing stability, and supports long-term operational safety. Buyers who prioritize quality and proven standards make smarter investments for demanding industrial applications.

Recent Comments